WE CAN BRING PRODUCT UPDATES AND IMPROVEMENTS INTO PRODUCTION, QUICKLY, ECONOMICALLY AND TAILOR-MADE TO YOUR SPECIFICATION.

The best engineering department in the business with more than 1,000 successful development projects built on the same principles that enabled PRUFREX develop its leading-edge solutions. We are your business development partner specialising in the modular small engine sector. Our very adaptable and modular engineering capability comes from the benefits of in-house design and production.

Market-relevant enhancements and optimization for controlling engines, burners and other electronically controlled applications can no longer be realised solely through mechanical means. We at PRUFREX are experts in open and closed-loop digital control intelligence, offering solutions that reflect your vision of the future. Our creative e-solutions will put you in the fast lane.

We’ll help you take your products to the next level through innovation!

We understand the goals that drive you as a manufacturer. And we know from our own experience what concerns you. Our workshop will provide inspiration that will open up new perspectives for your development and manufacturing departments. You will learn how control intelligence will help you to meet the challenges of tomorrow and gain that competitive edge over your competitors.

Dipl.-Ing. Martin Zappe,

Director Sales Division, E-Mail: workshop@pruefrex.de

Our design engineers are closely networked with our in-house production and international research teams. Here we develop innovative, technically feasible and affordable products for future markets.

Software development

Customer-specific

system solutions

Our embedded real-time systems utilise state of the art software modelling techniques using applications including Matlab/Simulink and Targetlink. Rapid control prototyping ensures fast development of control systems.

The software quality is ensured through the implementation of modern code analysis tools whilst customer-specific diagnostic functions make servicing easier.

Testing equipment development

Product-specific and fully

integrated into production

An experienced in-house team of testing and analysis specialists is responsible for the highest possible quality, focusing on delivering first class product that matches your expectations. The testing equipment is networked both to the production processes and automated production centers.

In-circuit, function, and product-specific tests ensure 100% testing coverage.

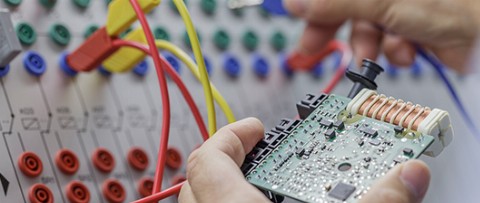

Hardware development

Complete systems at the

highest level

PRUFREX develops high-performance control units and ignition spark generators. Our hardware guarantees minimum footprint due to maximum integration. Featuring an EMC robust design, it provides support for all popular interfaces and protocols.

Our Hardware development team work closely with our in-house production department to ensure efficient prototyping and production-oriented engineering from the outset.

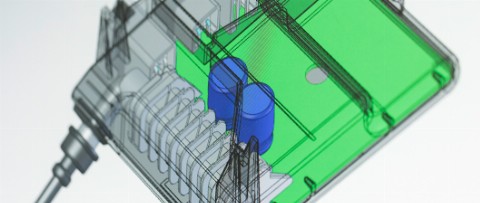

Engineering

From concept to production

By having our own in-house product and tool design, we are able to support development from concept through design safety and prototyping, all the way to the first production run.

RAPID prototyping with own 3D printer, in-house CAD/CAE development, and a broad spectrum of further analysis, simulation and design tools ensure the fulfillment of technical requirements and budgetary compliance.

Testing and analysis

Modern test stations, developed by Prufrex

Environmental tests, materials analyses, shock resistance measurements, thermal gradient tests, and endurance runs – shows how our testing and analysis department rates, tests and qualifies components and products under realistic conditions.

We safeguard all development phases with wide-ranging tests and require100% reliability for the final pre-delivery test.